Home > Cabinet Design and Manufacture

Cabinet Design & Manufacture

Over our 40 year history we have been involved in the production of a wide range of bespoke cabinet systems for an equally varied range of applications. The solution to your problem may be large, sophisticated, free-standing cabinet bay or simple controller unit to help you control a motor. Regardless of the scope of the project our specialist engineering team will endeavour to find a cost-effective solution.

Some of our customers already have their cabinet designed and just need us to help with manufacturing. Others comes to us unsure of what solution is right for them. Regardless of how much assistance you need our engineers are on hand to help you through every step of the process. From the initial designing of your cabinet through to building, testing and installation.

|

|

A Few Of Our Past Projects:

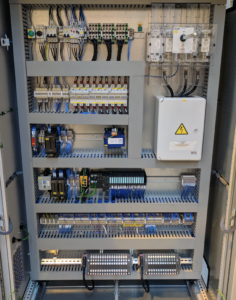

PLC Cabinet for Industrial Mixing Control System

This PLC cabinet built for an industrial mixing application which required stirring and valve control. It was part of much larger project that consisted of 7 cabinets total, 5 for motor control and 2 of PLC and HMI.

The system contains 10 Yaskawa GA700 inverter drives connected using a combination of digital control and serial communication monitoring. This allows the operator a high level of diagnostics to monitor for system issues or locating faults.

The entire system was designed and built in house by Goodwin Electronics. This included the PLC and HMI software design.

MCC Cabinet to Control a Fan and Ventilation System

This Motor Control Centre (MCC) cabinet was built for a customer who required a system to control a large fan and ventilation system.

The cabinet was designed with common bus-bar section, for cable entry and exit and each section was designed to include supply voltage monitor and motor controls at the customers request. The customer also specified all component use.

The system was fully tested at Goodwin Electronics with FAT carried out in house to the customers approval before being dispatched and installed by a 3rd party.

X-Range Variant Panel

These cabinets show the Goodwin Electronics X-Range inverter drive panels, built for customers requiring inverters to be housed within enclosures. The cabinet can be supplied in various configurations, for example:

One was built for a customer requiring 3ph 200V 50Hz output from a 1ph supply, the cabinet was supplied with a fitted socket and mating plug to allow the end user to wire and plug in their target apparatus.

One was designed to plug into a 13A socket and conveniently interface with lathe or drill press using simple start/stop controls and potentiometer for speed reference.

Other examples show more typical cabinets fitted with wall mounting bracket for ease of installation and using typical controls (start/stop or enable), main isolator and in some cases emergency stop.

Water treatment control cabinet design and build

These projects were based around different requests from one of our customers:

In one example we were requested to design and manufacture a power distribution and control cabinet to connect with a 3rd party specialised PSU cabinet.

The panel was for use in a water treatment environment within Europe and the panel controlled variable speed pumps, an external fan as well as providing an interface point for control valve and flow meter all connected to a Siemens PLC and HMI (supplied and programmed by the customer).

The project also required our assistance for FAT to interconnect the panels to the external devices.

In another example the customer provided the components and design and only required production and manufacturing work in producing a stainless steel cabinet suitable for a water treatment environment.