Home > Goodwin Projects

Multi-Stage Projects

Over our history we have been involved in a great many projects for a variety of customers looking at a wide range of different project complexities and demands.

Some have required purpose built electronics and embedded products to solve specific problems while others just involve a single cabinet build. For many of our customers their solution is usually somewhere in-between. Regardless a good many of our projects involve multiple areas of our expertise such as combining embedded software, PCB design, cabinet design, servo control and communication with other manufacturers products. Although many of our projects are linked to motion control or position sensing we have also been involved in projects outside these fields.

For these projects we have used a variety of Yaskawa motion controllers, servos and inverters as well as Omron PLCs and other manufacturers equipment depending on the nature of the requirements and customer demands or requests. Some projects have lasted a few weeks to others that have spanned years and lead to further expansion and developments.

A Few Of Our Past Projects:

Commercial vehicle servo system featuring bespoke enclosures, PCBs & software

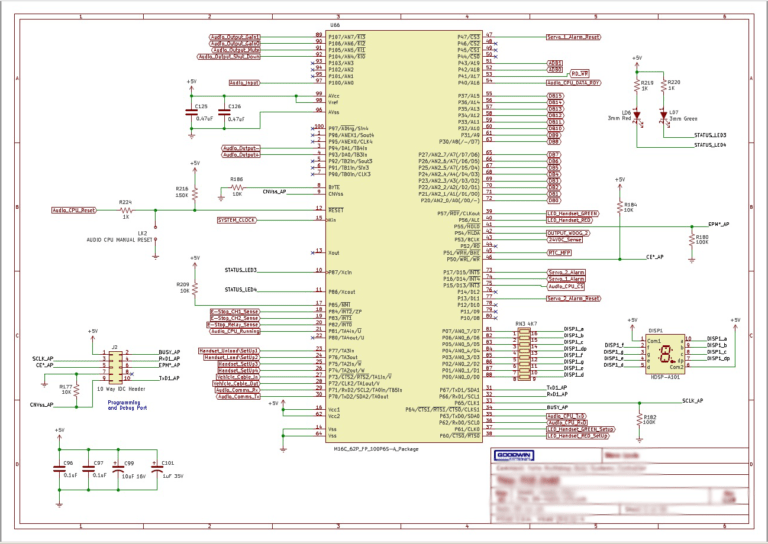

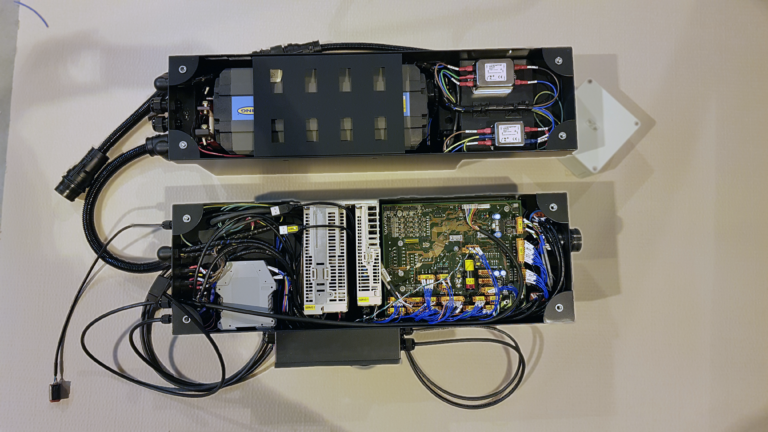

This project began as a proof of concept development and has now progressed to a demonstrator system, which is currently moving towards a pre-production unit.

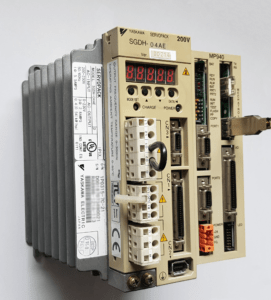

The development uses Yaskawa Sigma 7 servo motors to drive winch-based cables controlled by a bespoke PCB which handles the loading and unloading operations of a vehicle payload using 12V battery as power source inverted to provide a 230v ac supply.

Goodwin Electronics designed the electrical system and PCBs as well as writing the embedded software, developing and testing of the system.

Multi-cabinet production line temperature and motion control system

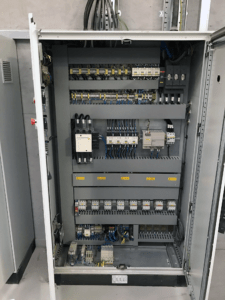

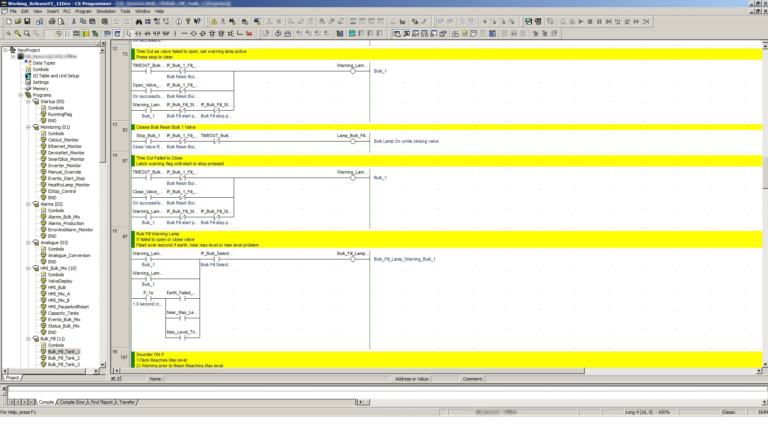

The Trim line shown in the pictures above is one of the two lines we have installed at this site. The Trim line controls continuous flow and curing process GRP moulding, including handling resin dispensing by reciprocating head, table and oven temperature for curing and line speed by controlled by main drive motor.

The line also handles the filling and mixing from 6 bulk storage tanks to 2 mixing tanks as well as controlling the various pumps and valve operation to release this operation.

The system consists of Omron PLC and Temperature controller, distributed DeviceNet IO control and over 10 Yaskawa inverters, including A1000 controlling reciprocating head motion via DWEZ program and DeviceNet. This equipment is distributed into over 15 control cabinets, all designed built and commissioned on-site by Goodwin.

Motion control system with customer PC user interface integration

Originally started as a project to provide a high performance Yaskawa MP controller and Sigma servo for a time critical axis the project grew over time to encompass a larger extent of the control for a variety of machines handling cable marking and processing for use in the transportation industry.

Over the last twenty years Goodwin Electronics have provided specification and supply of required hardware, and development and support of the software for three generations of Yaskawa MP controller and Sigma servo equipment.

For some machines with specialist functions a cost effective off-the-shelf solution wasn’t available so Goodwin Electronics have designed, developed and produced the hardware and software for custom embedded equipment which interface to the main controller to provide the required functionality.

Control cabinet design for an alternative energy harvesting system

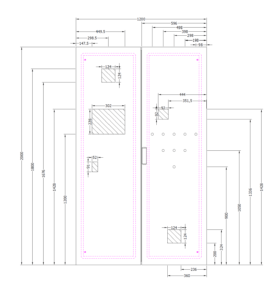

Working with partners within the renewable energy field as well as liaising with motor and inverter drive manufacturers the project was to extract electrical power from water movement due to tidal flow. The project was to be a proof of concept design and build to be tested in Orkney Isles with the extracted power dissipated as heat.

The system was to use two inverter drives with AC motors as generators by introducing flux field into the motors such that when motor is forced to rotate by tidal flow against attached blade, regenerative power is produced. The generator blades, 5m diameter, would be coupled to the motor and the system would be housed in 3 cabinets within a container mounted on a floating pontoon.

Proposed design was to use 2x 55kW AC motor with gearboxes and 2x Control Techniques M700 drives as well as Omron PLC and a HMI allowing user control and logging aspects but also allowing for autonomous operation.