Home > Software Development

Software Development

As with most electronics companies involved in control and motion applications, software engineering plays a large part in design and development work carried out, whether in development of specifications or programming of the operation or testing the final system.

We have worked with a variety of motion controllers, PLCs, HMIs, Microprocessors, Microcontroller and other programmable devices over the years on a wide variety of projects.

Our team has experience in a variety of programming environments and skill in Embedded software (typically ‘c’ language) and Yaskawa Motion Control software both standard and IEC, as well as Omron PLC ladder and scripted functions, HMI design for Omron and VIPA units and Yaskawa Inverter DWEZ programming.

A Few Of Our Past Projects:

Servo motion controller software development with HMI

For this project we worked with the customer to develop a specification for the upgrade of an old machine tool to remove obsolescence and provide new functions.

The ageing brushed DC servo motor on the feed axis of a horizontal borer was replaced using a Yaskawa Sigma V series servo drive and motor. A Yaskawa MP2600iec controller was fitted to provide control of the axis and through the use of the built in IO the existing control gear was also able to be simplified.

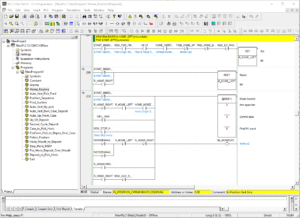

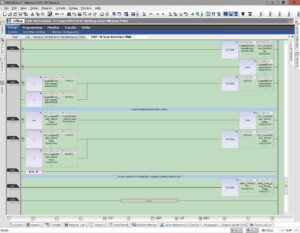

Software was developed for Yaskawa MP2600iec controller and VIPA HMI using Yaskawa MotionWork-siec and Progea Movicon software applications.

A number of manual operations were able to be replaced with automatic or semi-automatic functions reducing operator intervention and increasing productivity. The equipment upgrade provided opportunities for additional functions to improve process monitoring and increase machine

reliability.

PLC production line upgrade and restoration

While most software development is typically carried out at Goodwin Electronics, we are sometimes called on to work directly on site with the customer. In this example the customer had unfortunately suffered a catastrophic flooding at their facility and we were brought in to assist with the rebuild and retrofit a damaged production line.

They were also taking the opportunity to make some modifications to the packing format output of the line by increasing the number of cartons fitted within a box.

We were able to work with the customer and team of other suppliers to restore the production line to full operation and to modify the Omron PLC program and HMI screens for the new operation required, carrying out some work at Goodwin but most onsite.

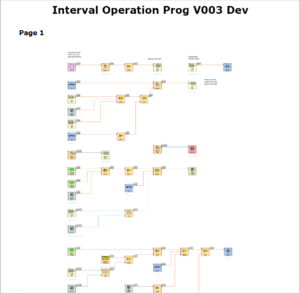

Inverter simple integrated timer operation

Although many of our projects end up being large multi-stage developments, they are not always so complicated. Some developments can be very simple and have a quick turn around.

In this application a customer required a very simple and low cost control operation to run a motor at a specific frequency for a certain time then stop for a certain length of time and repeat. Although the requirements could be achieved with external timers or a programmable relay the Yaskawa inverter internal PLC area was utilised to realise this operation.

Not only did this implementation reduce cost and cabinet size, require no external components but also provided end customer with full flexibility to change On and Wait times through the inverter parameters. We were also able to develop test and dispatch the solution within a couple of days allowing the customer to install the unit within a tight timeframe.

Internal products using embedded software portfolio

As well as project-based developments for customers we have also produced a variety of our own products over the years. Indeed the company first made its name producing DROs and CAM units, which can be traced back to the late 80s and 90s. Over this period we have developed many either microprocessor or microcontroller based products or occasionally PC based systems, often adding features such as real time clock, non-volatile or battery backed memory.

Many of our own products use ADC and DAC functionality for external control and general monitoring as well as digital input/output handling, additionally we often require line driver encoder read operation using our own bespoke circuitry.

For human interfacing we have worked with LCD, VFD and 7 segment displays and various types of keypad to provide the user information and allow parameters setup.

For communication we often work with serial protocol including CAN bus, RS484/RS422 and RS232 and Ethernet, often interfacing to PC applications including occasionally PC applications of our own design.

More information on these products can be found at Goodwin Products and Components.