Home > PCB Design and Manufacture

PCB Design & Manufacture

Goodwin Electronics has over 40 years in the control systems industry and over that time we have provided a wide range of bespoke solutions for an equally varied range of applications.

Goodwin Electronics specialises in designing and build of printed circuit boards (PCBs) many including microcontrollers and bespoke embedded software.

We have the ability to take your requirements, and, where there is a need which can not be met by standard products, we are able to design a product specifically to satisfy your criteria.

This can involve PCB design, electrical & panel design and embedded software.

Examples:

- Multistop for motion control

- Electronic rotary and linear sequential controllers

- Position control readouts

- HMI for leisure machines

- Custom software

Our experience and ability enables us to take your concept and develop it into a practical working solution to provide you with the optimum package for your needs.

A Few Of Our Past Projects:

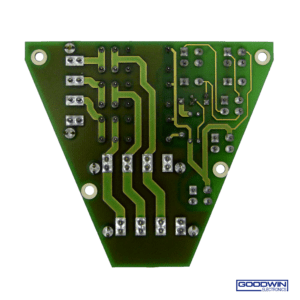

Re-developing an existing PCB design

This particular customer came to us requesting help modifying a pre-existing PCB designed and previously manufactured by a 3rd party that had since closed.

The customer provided the existing schematic and an existing PCB layout and Goodwin were able to make the required modifications along with other minor changes to improve durability and reliability by re-positioning components and increasing track widths. Goodwin were also able to arrange for PCB build, population, and testing in house to provide the customer with a complete solution.

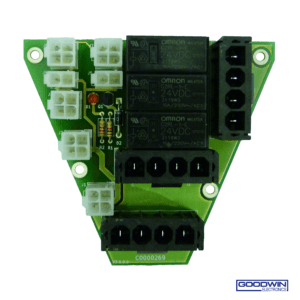

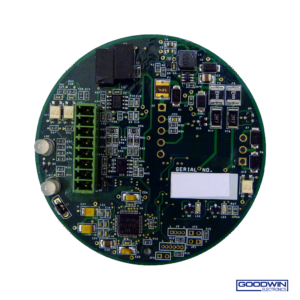

Dairy Industry control & monitoring PCB with embedded software

This application required a PCB capable of interfacing with CAN bus protocol and monitoring of the temperature and conductivity of a target solution as well as simple digital control of external solenoids and status display via tri-colour LEDs.

Customer was able to provide some example circuits but the majority of the PCB was newly developed by Goodwin, the PCB was constrained by size and shape due to the target housing. The customer was also able to supply some source code defining communication protocol and control which Goodwin were able to integrate into the new hardware platform firmware which also included auto and manual test routines and internal safety monitoring features. The project involved working with UK and European colleagues during the Beta testing phase and delivering a solution within a tight time frame for operation within the dairy industry.

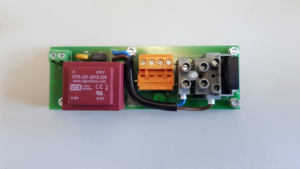

Upgrade and re-design for a timer system.

This project was based on a customer enquiry for a low cost PCB to replace an existing timer unit and to simplify system wiring. The PCB was required to be triggered by external push button input and drive an external 230V output for a fixed time period, the timer was also required to inhibit further trigger for a second time period.

A prototype unit was developed and a limited production run produced, then based on additional customer requirements a V2 PCB was created allowing power supply to and triggering from a NPN sensor in addition to pushbutton. Full test procedures and an automatic testing harness were produced in order to simplify the final test due to the volume ordered.

Working with our suppliers we were able to achieve unit cost less than £40 based on order of 1000 units over 12 month period, excluding development costs.

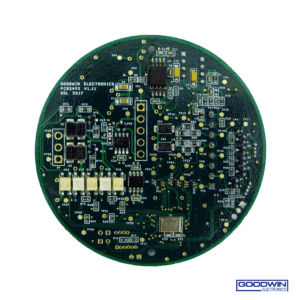

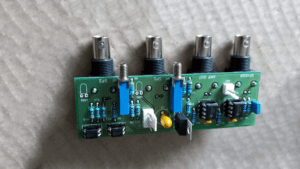

PCB design and production unit from prototype

In this case the customer had previously produced a circuit based on stripboard build but this was both labour intensive and liable to faults during build, making it unsuitable for even low volume production.

Goodwin were able to take the customer produced schematic and hardware prototype and turned it into a production unit with a custom designed PCB and enclosure labelling. Goodwin built, tested and supplied the finished unit with the housing more suited for the target industrial environment.